All the great properties of cork combined into a versatile and full-fledged facade finish with a 20-year manufacturer's warranty on our products.

With cork, you choose a wall cladding with many advantages. Firstly, spray cork is a very environmentally friendly wall cladding, made from organic materials. These are all regrowable materials, just like the vegetable oils and pigments added in the mixture.

With cork, you choose a wall cladding with many advantages. Firstly, spray cork is a very environmentally friendly wall cladding, made from organic materials. These are all regrowable materials, just like the vegetable oils and pigments added in the mixture.

It is a very decorative cladding, which can be applied to both modern and rural homes, when renovating or on new construction.

Spray cork is a decorative and environmentally friendly finishing coat that protects your home from weather and wind. With cork, oils and pigments as basic raw materials, the coating is an innovative alternative to traditional cladding systems.

With cork, everything is possible. The addition of natural resins gives this emulsion of cork granules very high adhesion values on most substrates. From concrete, stone and fibre cement over plastered and painted walls to metal and wood or plastic. The cork is coloured with pigments to obtain different colours. You can choose from a wide range of colours.

Cork is naturally hydrophobic and therefore cannot absorb moisture. This property of cork ensures that, once dried out, spray cork contains only 0.001% moisture and acts as an active moisture barrier for your facades.

So you get a completely, waterproof cork carpet over your entire facade that is still vapour-permeable, your wall can still breathe and moisture can still escape in the form of water vapour. (Water vapour permeability Class 1 Sd = 0.35m)

So you get a completely, waterproof cork carpet over your entire facade that is still vapour-permeable, your wall can still breathe and moisture can still escape in the form of water vapour. (Water vapour permeability Class 1 Sd = 0.35m)

Spray cork therefore not only has an insulating effect, but also a moisture-repellent effect. It is moisture-repellent and vapour-permeable. It will prevent moisture from the outside from penetrating the façade, and it will also allow moisture in the façade to escape. This avoids the risk of damp walls. Because the substrate is completely covered by spray cork, you no longer have thermal bridges and you will no longer suffer from condensation formations.

The insulating power of spray cork lies mainly in its good heat storage capacity. Sprayed cork has the interesting property that it can store heat and gradually release it, smoothing out temperature fluctuations indoors.

The insulating power of spray cork lies mainly in its good heat storage capacity. Sprayed cork has the interesting property that it can store heat and gradually release it, smoothing out temperature fluctuations indoors.

A characteristic of our spray cork is the addition of aerogel. Aerogel has exceptional insulating properties. It insulates up to 8 times better than known materials such as PUR and PIR foam, glass wool, rock wool, calcium, silicates or foam glass. Aerogel is fire-resistant and flame-resistant, water-repellent yet vapour-permeable. This makes corrosion less likely to occur, resulting in a longer lifespan.

The cork can withstand temperatures between -20°C and +177°C and is fireproof. Sometimes also used to encapsulate asbestos.

Cork has good acoustic properties, making acoustic insulation of large halls or open spaces perfectly possible. Because spray cork minimises vibrations and vibration in buildings, the material lends itself perfectly to sound insulation.

Spray cork also has a very high elasticity that absorbs minor shrinkage or expansion of the substrate. With a traction resistance and elongation at break of 35%, our spray cork certainly leads the European market.

Spray cork also has a very high elasticity that absorbs minor shrinkage or expansion of the substrate. With a traction resistance and elongation at break of 35%, our spray cork certainly leads the European market.

As the name suggests, spray cork is applied with a spraying machine. This is a way of working that allows for fast and accurate placement. Spray cork is applied in at least 3 layers with a total consumption of 2kg / m².

The cork used comes from cork oaks. These are very old and sturdy trees that can easily reach an age of 200 years.To obtain the cork, the trees do not have to be cut down. The cork bark is removed from the tree, and will simply grow back afterwards. Every 9 years, a cork oak can be stripped about 15 to 18 times during its lifetime

Not only are the materials themselves ecological, the production process of spray cork is also very ecological. Only a minimum of energy is consumed.

Bomuur, veelzijdig in gevelwerken

At Bomuur, we distinguish 4 types of facade treatment with spray cork:

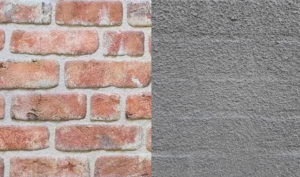

Type 1: Here we will clean the facade, install a greenstop and then immediately start spraying cork. The substrate is perfect and requires no further preparation. The shape of the existing surface is still visible through the sprayed cork.

Here we will clean the facade, install a greenstop and then immediately start spraying cork. The substrate is perfect and requires no further preparation. The shape of the existing surface is still visible through the sprayed cork.

Type 2:

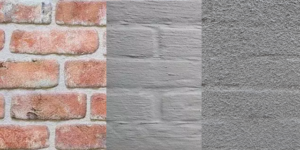

Here, after cleaning and installing a Greenstop, we will first caulk the entire façade with a primer coat of adhesive mortar with hydraulic lime and cork granules, so that all gaps and the joints are nicely evenly grouted.

Here, after cleaning and installing a Greenstop, we will first caulk the entire façade with a primer coat of adhesive mortar with hydraulic lime and cork granules, so that all gaps and the joints are nicely evenly grouted.

Damaged bricks are replaced. If necessary, we re-masonise where necessary to repair stone joints. This is always done in consultation with the customer.

Then we spray the cork in 3 layers in the colour of your choice (2kg cork/m²).

The shape of the existing surface is still visible through the sprayed cork.

Type 3:

After thorough cleaning, we will cement the facade. We install all the necessary corner and/or stop profiles. The walls are then cemented in 2 layers with a glass fibre reinforcement mesh embedded over the entire surface to prevent shrinkage cracks.

After thorough cleaning, we will cement the facade. We install all the necessary corner and/or stop profiles. The walls are then cemented in 2 layers with a glass fibre reinforcement mesh embedded over the entire surface to prevent shrinkage cracks.

The spray cork is then applied in 3 sprayed layers in the colour of your choice.

(2kg cork/m²)

Type 3 is perfect if you wish to repair walls in poor condition or hide unsightly brickwork. It is also the right choice for those who want to have a nice clean, plain and modern coat applied over their facade walls.

The shape of the existing surface is no longer visible thanks to the cementation and cork.

Type 4:

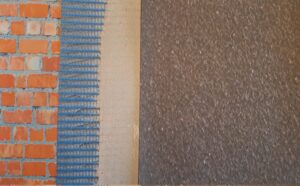

This facade finish has all the advantages of the previous one, but after placing an insulation layer on the facade.

This facade finish has all the advantages of the previous one, but after placing an insulation layer on the facade.

We install insulation panels made of expanded polystyrene (EPS), with a lambda or insulating value λ of 0.032 W/(m.K).

From 10 cm thick, you can apply for a premium of up to €30/m², we will be happy to help you with the paperwork.

After installing the insulation, we will cement it. We place all the necessary corner and/or stop profiles. The walls are then cemented in 2 layers with a fibreglass reinforcement mesh embedded over the entire surface to prevent shrinkage cracks.

The spray cork is then applied in 3 sprayed layers in the colour of your choice.

(2kg cork/m²)

The shape of the existing surface is no longer visible thanks to the cementation and cork.

Type 3, cementing and finishing with spray cork, from 2014 in Tournai.

Sprayed in 2 colours:

Before

After

Renovation

Step 1 of the 10-step plan: Request a no-obligation quote.

We will contact you as soon as possible and arrange the next 9 steps.